On the road again

Of the list of things to do from my last entry, I’ve completed all but one task, so I am ready for the OVR RallyCross Enduro Challenge on Saturday at National Trails Raceway in Columbus.

The new clutch took forever to get shipped from Autozone, but once it arrived I got it installed along with the new throw out bearing that was included and the used clutch cable that I sourced from the junkyard. While I was waiting on the clutch, I spent some time with my rotary tool grinding on the gear selector pin and was able to get all of the “additional” metal off, so now all four Booger Bushings are solidly connected. I also used some CRC MAF cleaner to start the process of cleaning off some of the oil, but I think that’s going to need a degreaser with a pressure washer.

Apparently, at the same time that bolt worked its way into the pressure plate, the connector for the coolant temp sender broke loose, so Megasquirt thought that the coolant was at about -40 degrees Fahrenheit. That caused the computer to try to enrich the heck out of the mixture so a new connector and some electrical tape later all is good on that front.

For the bobble strut replacement, I’m trying an experiment. I went to Ace Hardware and purchased a 10″ long 1/2″ eyebolt, a couple large washers, a 1/2″ nut, and a rubber stopper. I put a hole in the center of the stopper, pressed the stopper into the eye of the eyebolt, put the washers on either side of the eyebolt, and used a couple old nuts from the parts car as spacers. I bolted that up to the bobble relocation bracket attached to the K-member and then used an old sway bar end link bushing and some old washers from the parts car to bolt the top to the transmission. I suspect that the eyebolt is going to slide off the rubber stopper, but we’ll see what it looks like after the next event.

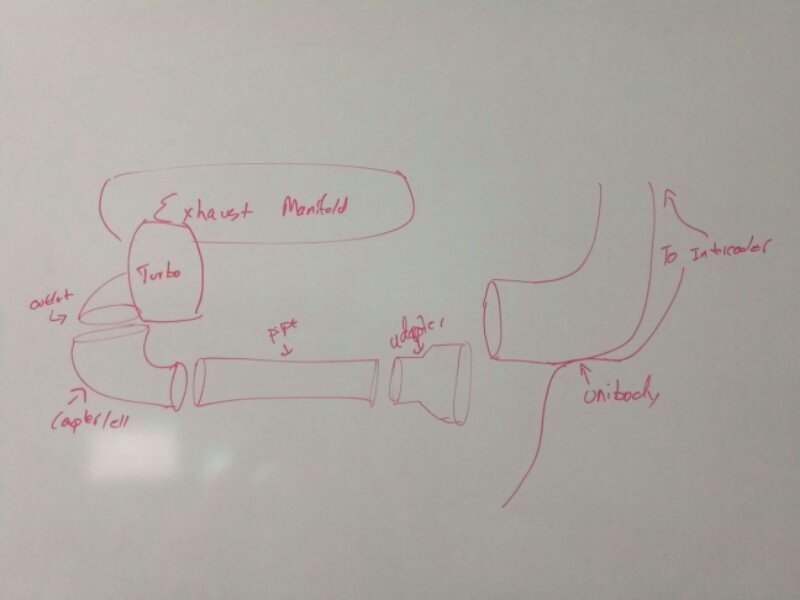

For the hot-side pipe, I think the real solution is to do what the SRT-4 does and run the charge pip straight down from the turbo, under the transmission, in front of the oil pan, and then into the intercooler. To do that, I’ll need some more exhaust bends and a lot of measuring, and a skidplate will get a lot more important. For now, though, I’m just going to treat the rubber sewage reducing coupler as a consumable and keep a couple extras in the car. Along with welding gloves.

All-in-all, except for the boost leak caused by a split in that coupler, I had it out last night and it’s running great.