Next time, I’m just going to live with the exhaust leak.

Ever since I put the car back together, there’s been a bit of an exhaust leak at the front. I thought it was the flex section on the downpipe, but before I started tearing in to things I thought it just might be a good idea to take a look and make sure. I’m not 100% convinced that the downpipe isn’t leaking, but I can tell for certain that the exhaust manifold gasket is leaking. Today’s lesson, then, is that while manifolds are super easy to install when the engine is on a stand, they’re a real pain in the neck when the engine is in the car!

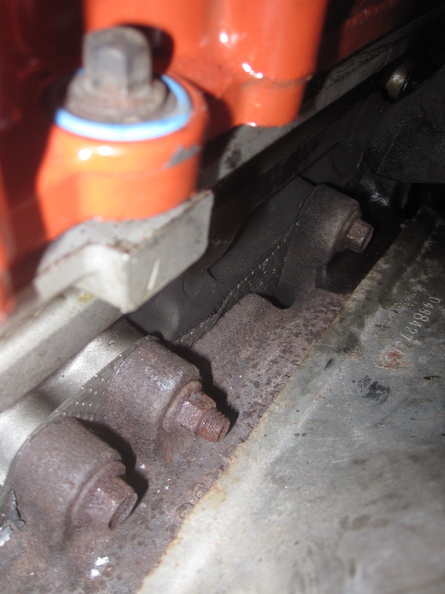

Here’s the offending gasket:

There’s enough air coming through there that I can feel it with my hand when the engine is idling. I’m not sure how it happened this way, but the manifold bolts were not fully tight. I’m not sure if I just forgot to torque them down or if they worked loose, but it managed to break up the gasket.

By putting that motor in this car, I’ve created a few serviceability issues that I need to work through. First up, the power steering reservoir and the coolant overflow bottle have a bit of a catch-22 removal process. The bottle needs to be unbolted and pushed down, and then you can get to the bolts holding on the reservoir.

As a reminder to myself, these oversized nuts (heh heh) are the mounting spacers:

Once that was out of the way, I was able to get the top manifold bolts off pretty easily:

The bottom, however, is a different story. I removed the top half of the heat shield so I could loosen the lower half. With that gone, I could get three of the four lower bolts out pretty easily. The fourth, however, is a real treat. Eventually, I removed the turbofold brace and relocated the heater core coolant lines a bit to gain access to the bolt that is basically under the turbo. Because of the heatshield and the oil and coolant lines running around behind the block, it is nearly impossible to get to that fourth bolt. While I was able to remove it after about two hours, I’m still not 100% sure how I’m going to get that bolt re-installed later. I guess that’s Future Bill’s problem, and what has he ever done for me, anyway?

My next challenge is getting the manifold back far enough on the studs to be able to slip the old gasket off and a new one on. I think I can do it without disconnecting any of the exhaust piping, however, I will need to rock the motor forward because there is not enough clearance between the firewall and the body of the turbo.

For now, I took a bit of a break to watch Bathurst and do family stuff. I’ll probably try to get a little farther along later tonight.

In the coming-soon department, I just purchased a KnockSense MS kit to be able to add knock detection to Megasquirt to try to keep from blowing this motor up. From srtforums.com, I found someone selling a stock intake manifold and throttle body so I should have those next week as well. The throttle body doesn’t have an IAC or TPS, so I’ll need to get those, but I’m going to see if the PT cruiser parts can be adapted in any way first. That should seal the engine up a little better since the intake wasn’t a perfect fit on the head and the 1gn Neon throttle body shaft has no ability to prevent boost from blowing through. Once I know what I’m doing for an IAC, I’ll pull MegaSquirt back off the car and add in the tach, idle control, and knock detection circuits all at once.