Once we returned from Nevada, the car needed to be delivered to the shop and arranged so we could work on it.

The spare had already been put on the rear to replace a tire that popped and now one of the front tires had also developed a significant hole. The growing number of completely flat tires combined with the mostly flat tires made it a little bit difficult to move around. Tim, Becca, and I were able to coordinate some floor jacks and a come-along to eventually get the Maserati to sit in the “project car spot”, though.

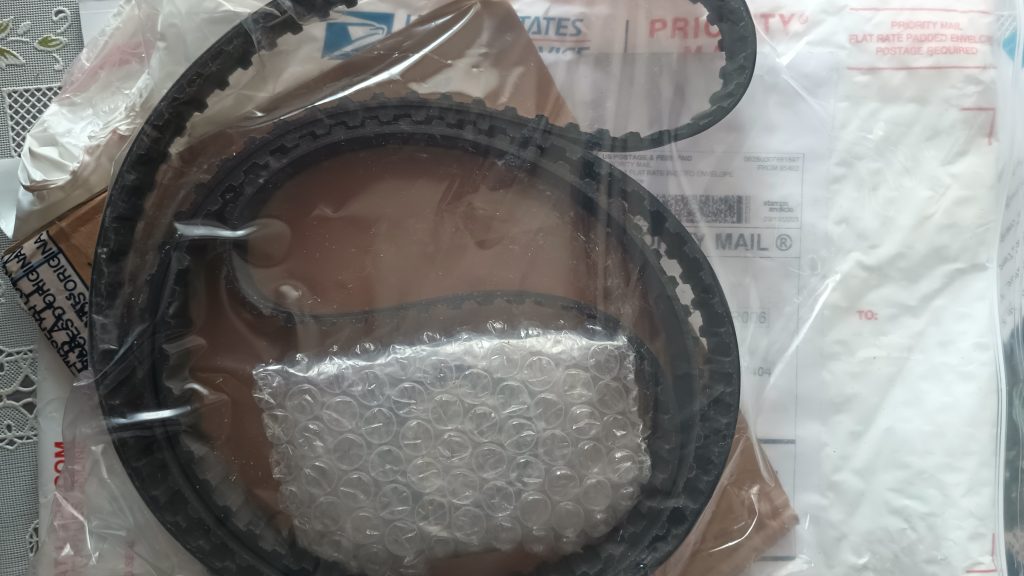

Now that the car was where I wanted it, it was time to begin the work! After careful consideration, we decided that because the cars were so prone to timing belt failure and it is an interference engine, the potential cost plus the risk of the timing belt failing while trying to start the car were both high enough that the first step should be to put a new timing belt on the car. For $114 after shipping and tax, I got a new Dayco timing belt and a bearing for the tensioner.

Greg, Tim, Becca, and I got started by pulling out the radiator, loosening the alternator, and removing the timing cover. Our first observation was that while the timing belt had definitely been replaced at some point judging by the broken-off and missing bolts on the cover, deciding to replace it now was a good choice. While the belt was intact, there were a number of small cracks already developing in it.

With the radiator out of the way, we gave the engine a little more of an inspection and noted that the oil in the crankcase does not appear to have any coolant or water in it and it is completely clean, as though the last thing that happened to this car before it was put up was an oil change. There are no visible holes in the block anywhere, but the vacuum system is a mess with cracked and missing hoses everywhere. There are a couple spots where the vacuum lines have been plugged with bolts. When we disconnected the radiator, we noted that the lower hose had been cut and there was absolutely no coolant anywhere in the system that we could see. We are assuming that the coolant temperature switch that controls the cooling fan has failed as the fan was connected to the alligator clips that were taped to the upper radiator hose.

As we were working we speculated a bit as to what made this a parts car and the theory that we’re working on right now is that it was taken off the road to do regular maintenance and because the fenders were damaged and/or rusty. The car has new fenders welded on, but the body work isn’t complete. That would explain why the whole lights, bumper, and grille assembly is removed since that would need to come off to do the fenders. I suspect that the body work was started and the car was sold as an unfinished project at a price that was cheap enough to make it good to stick in a field as a parts car. Looking at the mileage, it’s just a few hundred miles past the timing belt change:

That’s my theory at least.

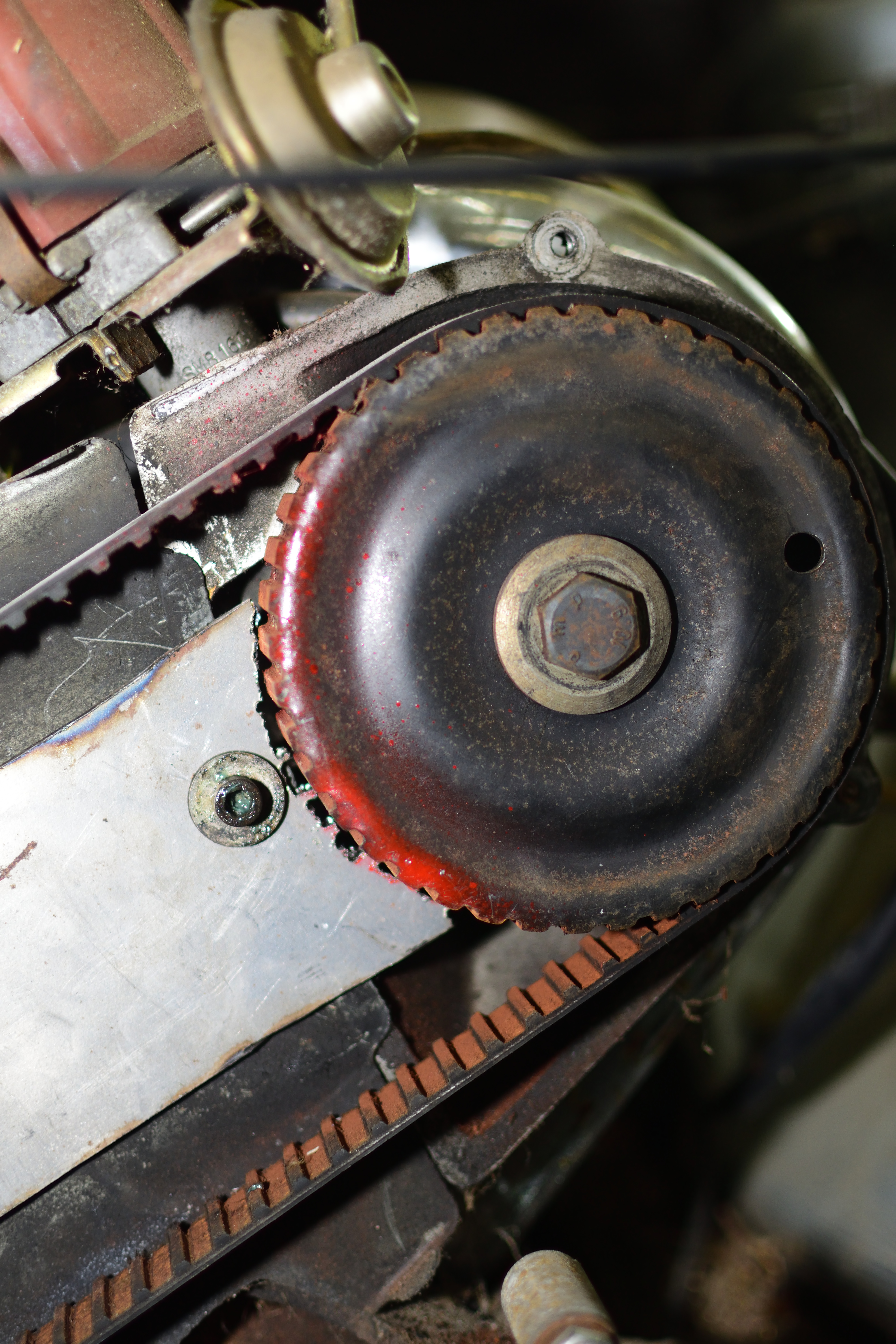

According to the service manual, the right cam will stay in place when the engine is a TDC and on the timing marks, but the left cam must be held in place. Naturally there’s a special tool for that, but we don’t have one. So using a bit of leftover steel, I cut out some teeth and put a hold in it to bolt it down to the block. We got as far as testing my cam gear holder by trying to rotate the engine and it seems to work. Next up will be releasing the tensioner – or the “belt stretcher” as the manual calls it – and pulling the crank pulley and the tensioner bearing so that the old belt can be removed and the new one installed.

The tool is imperfect, as evident by the above photo, but it does hold the cam in place. Cutting that out would have been much easier with a loose pulley to use for better measurements and fitment since the transfer from paperboard to steel resulted in the teeth being off a bit as the paperboard was bent a little behind the pulley. Being extremely unlikely that this tool will ever be used a second time, however, it should get this job done and then be returned to the scrap steel pile to find another life once the new timing belt has been installed.