Today I feel like I just sort of ran in place. I didn’t get to clear very many things off of my to do list and I’m absolutely at that hyper-nervous part where I’m not sure that this is going to actually work out.

As previously mentioned, there’s a leak at the radiator and I was able to confirm that it is coming from the temperature switch for the cooling fans. After draining out the coolant from the radiator, I removed the sensor and verified that it is not working. I can get a new one for around $25, but I don’t think it will arrive in time for me to be able to continue testing, so replacing that switch is going to be a “later” item. For now, I need to seal it up. You can see that the sealing ring is a little grody.

I tried cleaning it up a bit and putting an o-ring on it.

That didn’t work. I’m trying a little bit of rtv right now in place of the sealing ring and the o-ring and if that doesn’t work, I may just put a coating of JB Weld around it to seal it. Or I might go ahead and make a bit of a larger order from Lenny at Auto Italia and just deal with knowing that I’m going to be leaking a bit while I test.

Moving on from that, I found an item that needed to be corrected but wasn’t on the list: The nuts holding the torsion rods to the subframe were pretty loose, so I torqued them down. Not worth a picture of that.

I stopped by the hardware store and got a bit of lawnmower air filter to make some filters for the valve cover breathers. While I was there, I got a big bin to store all the spares so that I could empty out the car.

Using some old scrap of exhaust pipe, I made a couple little tubes to go between the air filters and the low pressure charge pipes. I rotated the elbows around from their more flat orientation for the stock airbox so that the air filters will stand up and hopefully get some cooler air.

I also broke out the smoke tester and vacuum pump again. There’s a lot of smoke that comes from the secondary advance unit on the distributor and when I put pressure or vacuum on it, nothing seems to be happening. What’s weird about that is that when we didn’t have that connected before, the car didn’t run right at all, but once it was hooked up things got better. So maybe it is doing something after all, but that’s going to require more investigation at some point. I think that the vacuum portion can be removed from the bottom of the distributor, the bells can be opened up, and the diaphragms can be repaired.

Another sign of failure was that the fuel pressure regular does not hold a vacuum. It will pump up a bit and then fairly quickly drop back down. Fortunately, the car came with a spare and that one does hold vacuum. If that diaphragm is not sealing, then it’s very likely the fuel pressure is too high and also possible that extra fuel is coming in through the vacuum line. So I’ve swapped out the pressure regulator with the spare and hopefully that will help with the rich running.

Finally, I worked out how the rear bumper gets mounted and found most of the hardware to do so. I’m going to need a pair of M10x1.50 nuts to get the job done, but it should be a pretty quick job.

At this point, I need to start really planning out the time that I’m going to take to get things done. Cutting the numbers and other vinyl I can do over Easter while we’re traveling to see the in-laws. If the turbo rebuild kit comes in before we leave for that, I can also try to pull the turbo off and take it with me and do that on the road as well. I’d really like to wait for the plugs and wires to come in before I do any more testing of how it runs and drives but that may not be realistic. I’ve got 5 gallons of fresh 93 octane and a bottle of Seafoam that I’d like to start running through it to see if between that, and the fuel pressure regulator being replaced, things are any better.

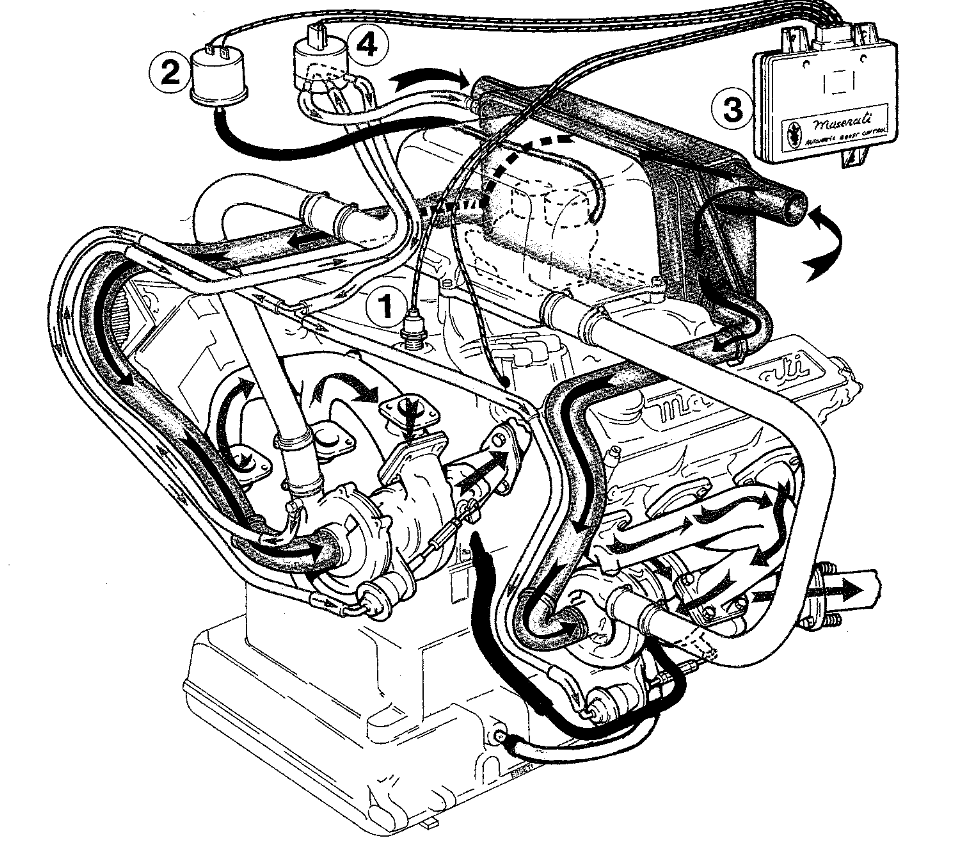

Finally, I was able to track down how the boost control system works thanks to the diagram from the service manual:

There was a line hanging off of the wastegate control valve (#4 in the above picture) that had a bit of tape over it and I wasn’t sure what the deal was. The way the system works, apparently, is that it gets its boost reference signal at the pressure transducer (#2) and watches the engine performance from the knock sensor (#1). The wastegate solenoid then opens up on command from the computer to push the little arms and bleed off pressure. But I think that the valve also works as the blow off valve, dumping the pressure from the right turbo, through the valve, and out what I have identified as the mystery hose. I may stick a little foam over that as a filter, but that is a loose connection that doesn’t need to be worried about at this time.