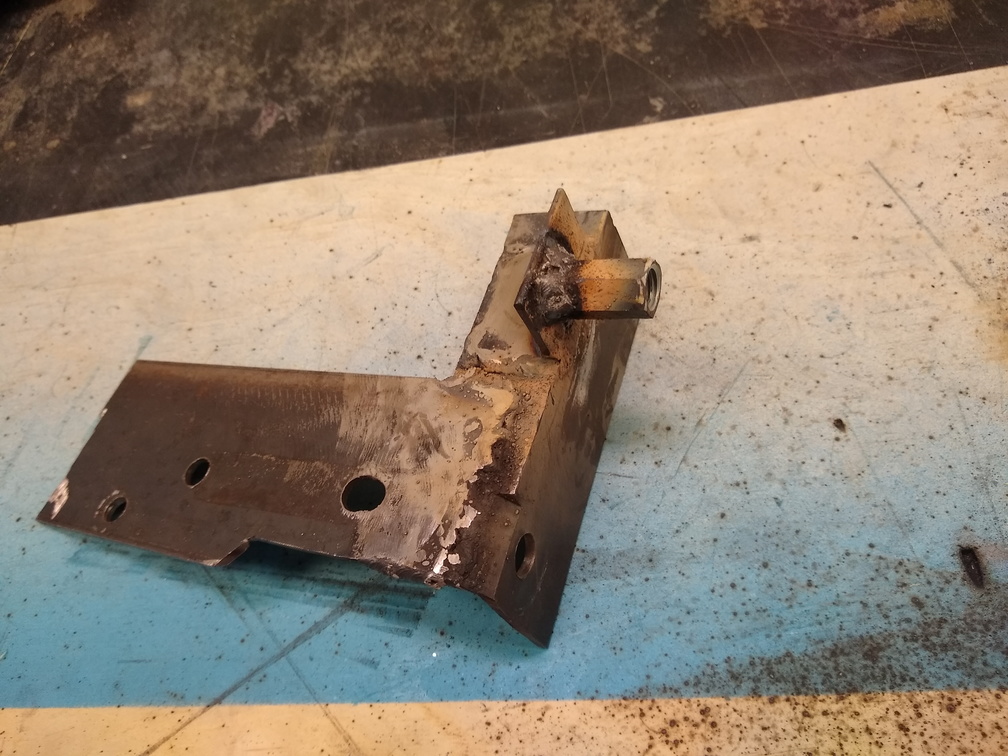

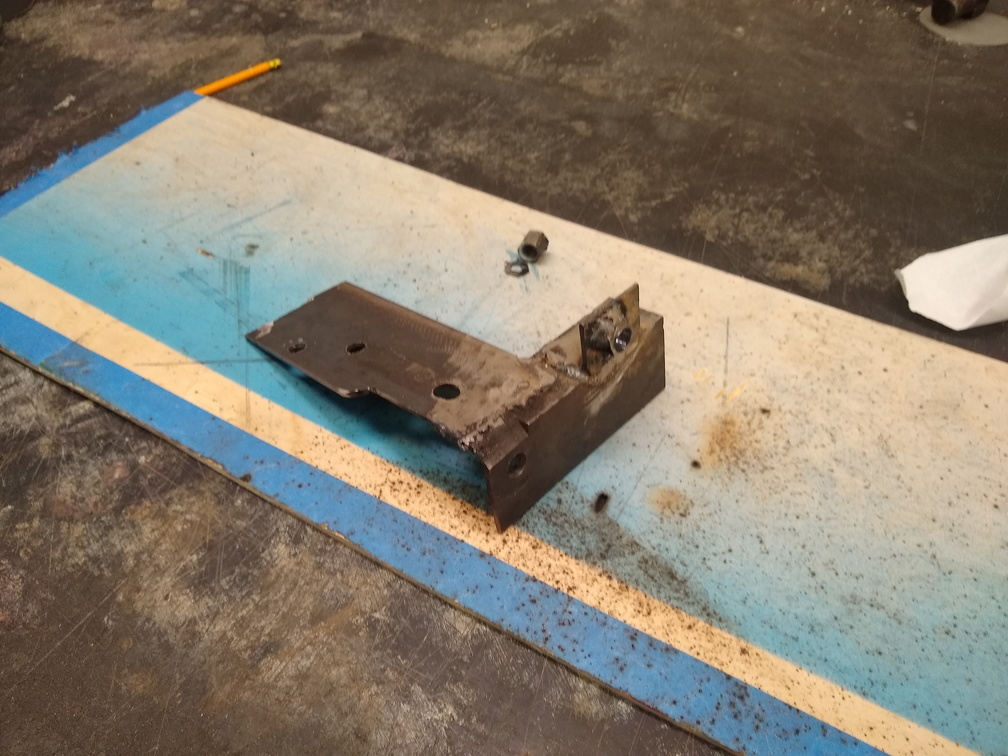

The engine/transmission portion of the engine-side front motor mount bracket is all put together and ready. The bolt holes all line up, even though the bolts themselves need to be replaced with ones that aren’t quite so lengthy. The coupler nut was used as a spacer and rather than trying to hold it carefully while cutting it, I welded it up first and then ground it down.

Once the size was correct, I put it in the drill press and drilled the coupler out to 1/2″ and as the first picture in this update shows, the gap is filled in nicely with a little bit of steel. Oh, and I did go all the way around – including the ends – and grind off the zinc coating before I hit it with the MIG.

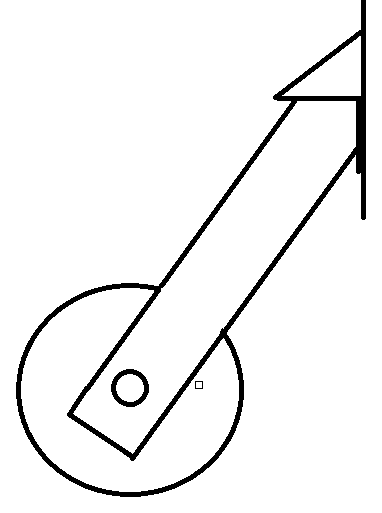

Next step is to get the engine secured into place where I want it to actually sit and then bolt up an old body-side front motor mount that I’ve got hanging around. With some cardboard, I should be able to find a good path for the braces that will go up to the engine-side bracket. From the side, it should wind up looking something like this (not to scale):

The brace will be angle iron and there will be some additional bracing done to that of course. At the top, the bracing will terminate in upside-down angle with some gussets along the top to provide strength.

I know I’ve missed a bunch of events so far this year, but it is starting to come together! Finally.