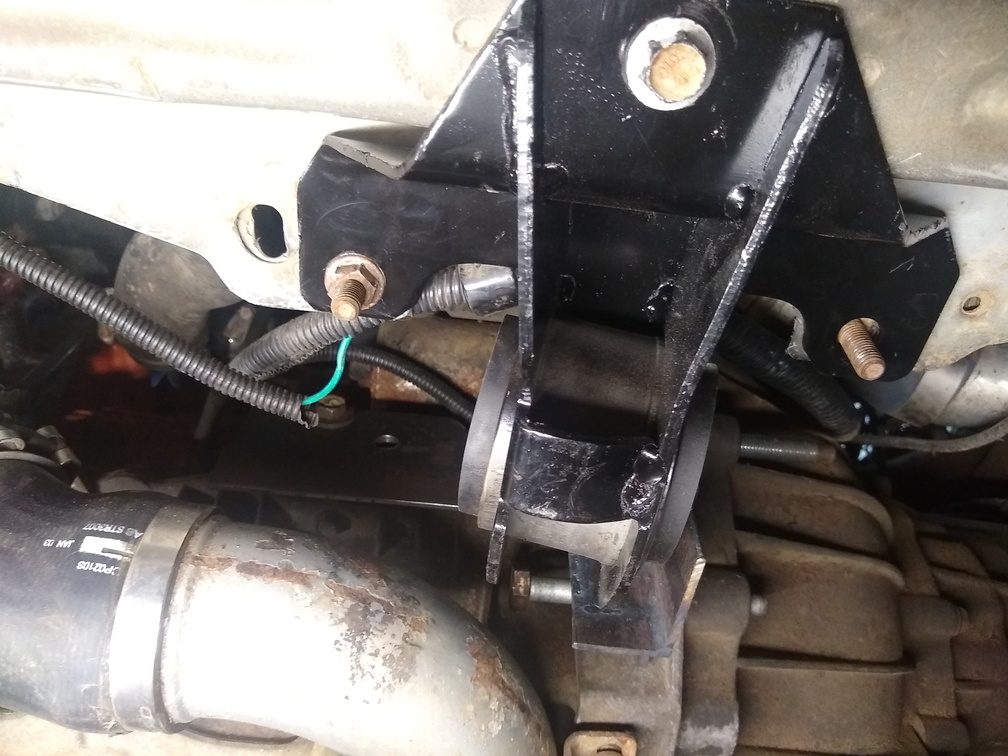

Now that the engine-side mount bracket is built, the connection between it and the body-side bracket needs to be made. Using some reclaimed hardware from a Ford Focus, I bolted up the body-side mount and used the captive stud to finish bending the bottom of the core support into place.

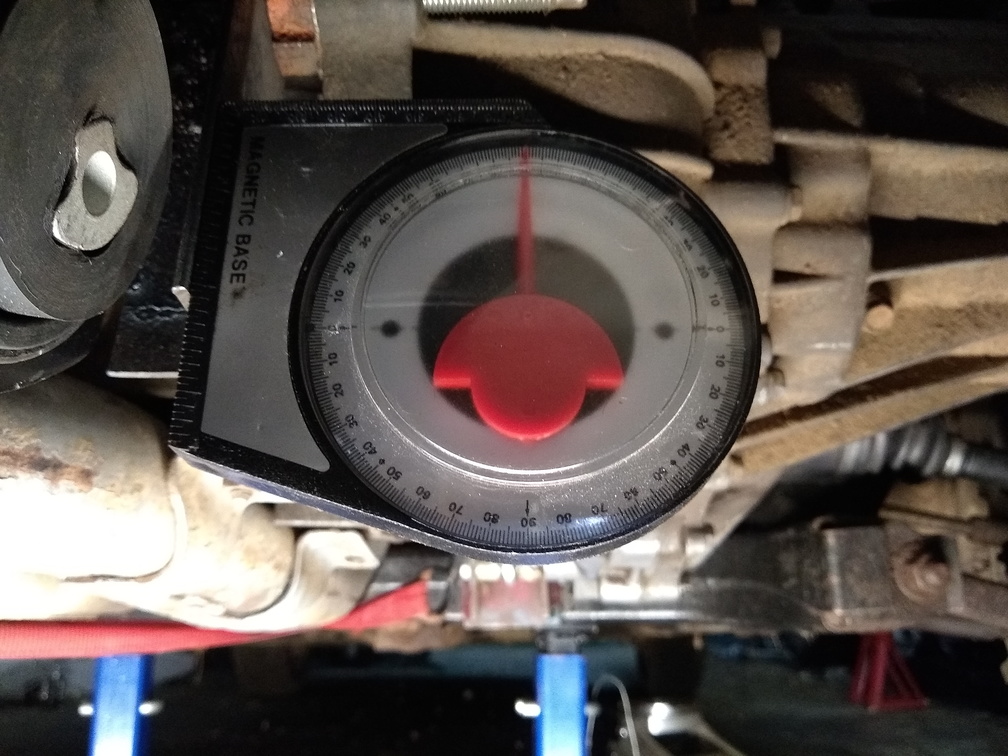

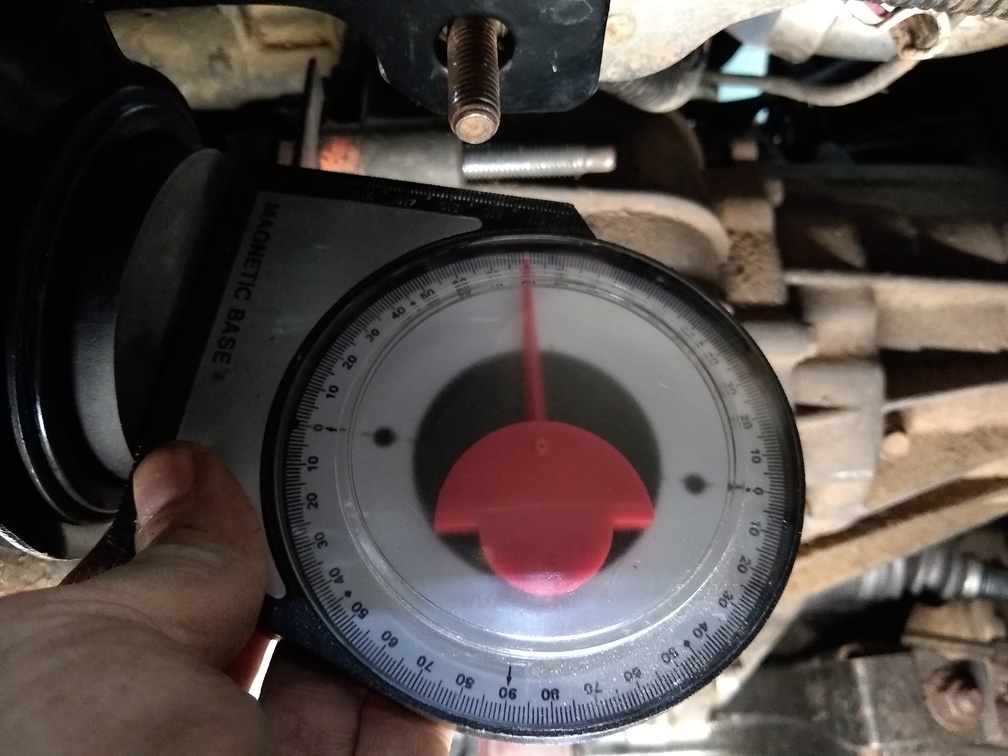

When I started this process, there was the knowledge that things were at a bit of an angle, but dealing with that was a “later” problem. It is now officially “later” and this is what I need to deal with:

The two brackets are also much closer together than I had envisioned in my head, even though I knew they were going to be close. That will work in my favor, presenting me with less material to flex and then break. Based on what I can see, it appears that it’s about a 10 degree cant to the right.

Other important numbers that I’m going to need for later:

- The rubber part of the mount is 70mm in diameter

- The overlap of the body-side mount to the engine-side mount is about 10mm deep x 62mm long

- The right side of the car (left side in the pictures) is 140mm from the rubber insert to the engine-side bracket

How I use that information is yet to be determined, but I’m thinking about ways to trim up the engine-side bracket and then attach some angle iron. I also don’t remember exactly how or why the original 1gn engine-side bracket didn’t fit, so I may try to find that and see if it might just be easier to modify that or cut it up and attach it to the engine-side plate that I already made.